Competitive Price for High Viscosity Cellulose Ether Hydroxypropyl Methyl Cellulose HPMC

We keep on with the basic principle of “quality to start with, support very first, continuous improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Competitive Price for High Viscosity Cellulose Ether Hydroxypropyl Methyl Cellulose HPMC, Therefore, we are able to meet up with different inquiries from different purchasers. Remember to discover our website to check a lot more information from our products.

We keep on with the basic principle of “quality to start with, support very first, continuous improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for , All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

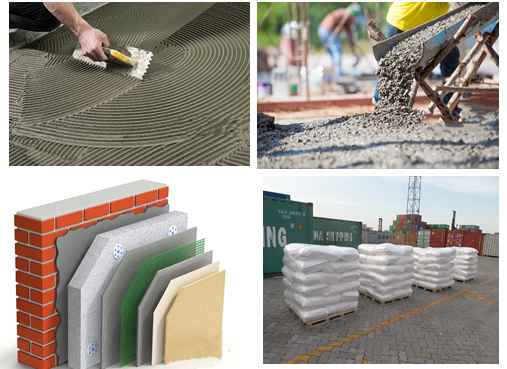

Hydroxypropyl Methylcellulose (HPMC) Construction Grade are widely used in Tile adhesives, dry mixed mortar, wall putty, Skim coat,joint filler, self-levelling , cement and gypsum based plaster etc.We can provide both non-modified grade and modified grade HPMC, which has long open time, good water retention, excellent workability and Good slipping resistance etc.

1. Chemical Specification

| Specification |

60AX ( 2910 ) |

65AX ( 2906 ) |

75AX ( 2208 ) |

|

Gel temperature (℃) |

58-64 |

62-68 |

70-90 |

|

Methoxy (WT%) |

28.0-30.0 |

27.0-30.0 |

19.0-24.0 |

|

Hydroxypropoxy (WT%) |

7.0-12.0 |

4.0-7.5 |

4.0-12.0 |

|

Viscosity(cps, 2% Solution) |

3, 5, 6, 15, 50, 100, 400,4000, 10000, 40000, 60000,100000,150000,200000 |

||

2. Product Grade:

| Product Grade | Viscosity(NDJ, mPa.s, 2%) | Viscosity(Brookfield, mPa.s, 2%) |

| HPMC 75AX400 | 320-480 | 320-480 |

| HPMC 75AX60000 | 48000-72000 | 24000-36000 |

| HPMC 75AX100000 | 80000-120000 | 38000-55000 |

| HPMC 75AX150000 | 120000-180000 | 55000-65000 |

| HPMC 75AX200000 | 180000-240000 | 70000-80000 |

3. Application fields:

1)Tile Adhesives

•Better workability: lubricity and plasticity of plaster is ensured, mortar can be applied easier and quicker.

•Good water retention: prolonged opening time will make tiling more efficient.

•Improved adhesion and sliding resistance: especially for heavy tiles.

2)Dry mixed mortar

•Easy dry mix formula due to cold water solubility: lump formation can be easily avoided, ideal for heavy tiles.

•Good water retention: prevention of fluid loss to the substrates, the appropriate water content is kept in mixture which guarantees longer concreting time.

3)Cement/Gypsum based Plaster

•Increased water demand: increased open time, expanded spry area and more economical formulation.

•Easier spreading and improved sagging resistance due to improved consistency.

4)Wall putty/Skimcoat

•Water retention: maximized water content in slurry.

•Anti-sagging: when spreading a thicker coat corrugation can be avoided.

•Increased mortar yield: depending on the weight of the dry mixture and appropriate formulation ,HPMC can increase the mortar volume.

5)Exterior Insulation and Finish System ( EIFS )

•Improved adhesion.

•Good wetting ability for EPS board and substrate.

•Reduced air entrancement and water uptake.

6)Self-leveling

•Protection from water exudation and material sedimentation.

•No effect on slurry fluidity with low viscosity

HPMC, while its water retention characteristics improve the finish performance on the surface.

7)Crack Filler

·Better workability: proper thickness and plasticity.

·Water retention ensures prolonged work time.

·Sag resistance: improved mortar bonding ability.

4.Packaging

The standard packing is 25kg/bag

20’FCL: 12 ton with palletized; 13.5 ton unpalletized.

40’FCL: 24 ton with palletized; 28 ton unpalletized.

Cangzhou Bohai New District Anxin Chemistry Co., Ltd. is a professional Construction Grade Hydroxypropyl Methylcellulose(HPMC) cellulose ether manufacturer in China, located in the Lingang Economic and Technological Development Zone Chemical Park,Cangzhou Bohai New District, a national level chemical park, close to Beijing,Tianjin and Shandong . 80KM distance to Tianjin seaport.

The production capacity is 27000 tons/year. The products are: Hydroxypropyl Methyl Cellulose (HPMC), Hydroxyethyl Methyl Cellulose (HEMC), Methyl Cellulose (MC), Hydroxyethyl Cellulose (HEC), Ethyl Cellulose (EC) etc.We keep on with the basic principle of “quality to start with, support very first, continuous improvement and innovation to meet the customers” for your management and “zero defect, zero complaints” as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Competitive Price for High Viscosity Cellulose Ether Hydroxypropyl Methyl Cellulose HPMC, Therefore, we are able to meet up with different inquiries from different purchasers. Remember to discover our website to check a lot more information from our products.

Competitive Price for Hydroxypropyl Methyl Cellulose and HPMC, All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

Cangzhou Bohai New District Anxin Chemistry Co., Ltd. is a leading cellulose ether manufacturer, specializing in AnxinCel® HPMC, MHEC, HEC,CMC,RDP.

1. HPMC Hydroxypropyl Methylcellulose

2. MHEC Hydroxyethyl Methyl Cellulose

3. Hydroxyethyl Cellulose (HEC)

4. Sodium Carboxymethyl Cellulose (CMC)

7. Redispersible Polymer Powder (RDP)

AnxinCel® cellulose ethers are used in a wide range of industries including construction, pharmaceuticals, and food processing.